BMC is the abbreviation of glass fiber reinforced unsaturated polycrystalline thermosetting plastic. It is currently the most widely used type of reinforced thermosetting plastic.

Whether it is screw type or plunger type, an extrusion type feeding device must be attached to force the material into the barrel. This feeding device mostly uses plunger type pressure-feeding.

Characteristics and applications of BMC Molding

BMC has good physical, electrical and mechanical properties, so it has a wide range of applications. For example, it can be used to make mechanical parts such as gearbox components, intake pipes, valve covers, bumpers, etc.; in applications that require earthquake resistance, flame retardancy, aesthetics, Durable aviation, construction, furniture, etc. are also widely used; in its traditional electrical field, its uses are becoming more and more extensive.

4) Mold clamping device

1) Feeding system

Several mold clamping devices, such as mechanical, hydraulic and fully hydraulic, are mostly used.

5)Mold

2)Injection molding system

Because the injection volume of the plunger injection molding machine is accurate and constant, the glass fiber is dispersed in the melt with less damage. Therefore, the plunger injection molding machine is used more often, but the exhaust is inconvenient.

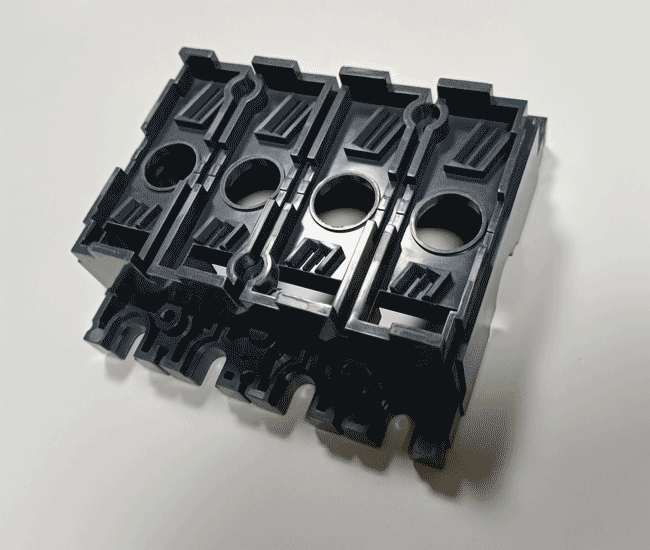

BMC injection molding is somewhat different from ordinary thermoplastic and thermosetting injection molding. The main reason is that BMC has a lower shrinkage rate, so the mold cavity size should be changed.

3)Heating system

Additional resources:In BMC injection molding, it is very important to control the temperature of the barrel. There must be a control system to control the temperature to ensure that the temperature from the feeding section to the nozzle is optimal. Currently, constant temperature water or constant temperature oil is used for heating. Electric heating can also be used.

BMC’s injection molding process

1) Barrel temperature and mold temperature

During injection molding, BMC is required to maintain low viscosity flow behavior for a long time under the barrel temperature; generally, the barrel temperature should be able to meet the lower limit of BMC. The temperature of the barrel is generally divided into two or three stages of control. The temperature near the hopper is lower and the temperature near the nozzle is higher. Generally the difference is 20-60C, and the mold temperature is generally controlled at 135~185C;.

2) Injection pressure

Because BMC has poor fluidity, fast solidification, and complex mold structure, the injection pressure should be higher, generally 80~16 OMPao.

3)Injection speed

Increasing the injection speed will help improve the surface quality of plastic parts and shorten the curing time, but it is not conducive to exhaust and increase the degree of glass fiber orientation. - Therefore, a lower injection speed should be used while ensuring the surface quality of the plastic part, usually 1.8-3.5m/min.

4) Screw speed and back pressure

If a screw injection molding machine is used, the screw will cause greater damage to the glass fiber when injecting BMC. In order to minimize the damage to the glass fiber, the screw speed should be selected at a low value, generally 20~5Or/min. According to the viscosity of BMC, it is appropriate to use low back pressure, generally 1.4-2.0MPa.

5) Molding cycle

Due to the different size and complexity of plastic parts, the process time of each stage is also different. Generally, the injection time is 2~20s and the heat preservation time is 10-20s/mm (thickness).

Previous: Is Aluminum Extrusion Technology the Future of Sustainability?

Next: None

Comments

Please Join Us to post.

0