Technical economy of ring rolling

Ring rolling technology came into being along with the development of the railway transportation industry. Since the mid-19th century, the rapid development of railway transportation has greatly increased the speed and load capacity of trains. The cast iron wheels of trains cannot meet the requirements of high-speed and heavy loads, so people equip the cast iron wheels of trains with better-performing and replaceable steel wheels. In order to produce train wheels, Britain built a wheel rolling mill in 1842, and in 1886 the Ostrovi Foundry in Russia established a train wheel production workshop. Subsequently, ring rolling technology was not only widely used in the production of train wheels, but also gradually promoted in aerospace, petrochemical and other engineering machinery. The application of ring rolling technology in our country began in the 1950s. Now, ring rolling technology has become one of the efficient, advanced and main process methods for the production of ring mechanical parts, and is developing rapidly in the following directions.

The ring rolling process is usually implemented on a production line that combines forging hammer - ring rolling machine, flat forging machine - ring rolling machine, forging hammer - press - ring rolling machine and other equipment. It is free from traditional ring forgings. Compared with the forging process and the die forging process of ring forgings, it has better technical and economic effects, which are specifically reflected in the following aspects;

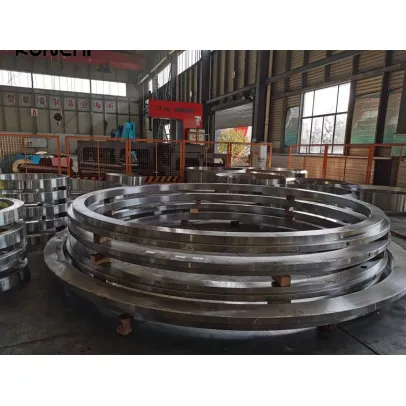

(1) Large-scale. Large ring forgings with a diameter of more than 2000mm are increasingly produced using the ring rolling process, while the original horse frame enlarging process is gradually being eliminated due to high labor intensity, low productivity, low dimensional accuracy of forgings, and large machining allowances. The number of ring rolling equipment with a diameter of 2000mm ~ 10000mm has increased rapidly in the United States, Germany, the United Kingdom, France, Japan, Russia and other countries. my country has also introduced ring rolling equipment with a diameter of 3000mm ~ 5500mm from Germany.

(1) High precision, small machining allowance, and high material utilization. The geometric accuracy of roll-formed ring forgings is equivalent to that of die-forged ring forgings, the rough punching holes and skin are small, and there is no flash loss. Compared with the free forging process, the precision of rolling forming ring forgings is greatly improved, and the machining allowance is greatly reduced.

(2)High speed. As the degree of mechanization and automation of ring rolling equipment and its loading and unloading auxiliary equipment increases, the ring rolling speed and productivity increase rapidly. On the small bearing ring rolling forming automatic production line, not only the blanking, heating, breaking, and rolling forming processes are automated, but the productivity reaches 300 pieces/h to 1,000 pieces/h.

(2) The internal quality is good. The internal structure of the rolled-formed ring forgings is dense, the grains are fine, and the streamlines are distributed along the circumferential direction. Its structural properties, wear resistance and fatigue life are significantly higher than those of ring forgings forged or machined by other methods.

Additional resources:

(3) Precision. With the refinement of billet making and the advancement of ring rolling process measurement and control systems, the accuracy of ring rolling has gradually improved, and precision ring rolling technology has developed rapidly. At present, the diameter and dimensional accuracy of ring forgings formed by precision rolling can reach 1/1000.

(3) The equipment has small tonnage, low investment and a wide range of forging diameters. Rolling deformation realizes the deformation of the entire forging through the accumulation of local deformation. Compared with the overall die forging deformation, the deformation force of the rolling ring is greatly reduced, so the tonnage of the rolling forming equipment is greatly reduced, and the equipment investment is greatly reduced. Generally, the diameter range of ring forgings that can be processed on ring rolling equipment is large. The maximum diameter and minimum diameter differ by 3 to 5 times, and the maximum weight and minimum weight differ by dozens of times. This is difficult to achieve with other processing equipment.

(4)Complication. Generally, rolling rings are mainly used to produce ring parts with rectangular or approximately rectangular cross-sections. Ring forgings with complex cross-sections are usually simplified into ring parts with approximately rectangular cross-sections and then mechanically cut. However, in order to reduce the amount of machining and improve the quality of ring forgings, Material utilization, the technology of producing complex cross-section annular forgings has been highly valued and developed rapidly. By optimizing the ring blank for rolling forming and rationally designing the pass shape for rolling forming, many ring forgings with complex cross-sections can be directly rolled into shape.

(4) High productivity. The Rolled Ring Forging speed of ring rolling equipment is usually 1m/s ~ 2m/s. The forming cycle is generally about 10s, with the shortest reaching 3.6s. The maximum productivity has reached 1000 pieces/h, which is much higher than that of free-forming equipment. Productivity of forged and die forged ring forgings.

(5) Flexibility. In order to meet the needs of producing rings in small batches, multiple varieties, and multiple specifications, flexible ring rolling equipment that can quickly change the forming hole pattern and conveniently adjust working parameters has received attention. The current flexible ring rolling equipment's forming pass replacement time is 1.5h~2h, the diameter of the ring forgings is 250~900mm, and the weight is 20kg-100kg. It is very suitable for small batch rolling forming production with a batch size of 50 pieces.

(5) Low production cost. The rolling ring has the comprehensive advantages of high material utilization, less machining hours, low production energy consumption, and long rolling forming pass life, so the production cost is low. For 3500mm × 110mm × 90mm carbon steel ring-shaped parts made in Germany, the production cost of free forging is 77% higher than that of roll forming; according to statistics from the former Soviet Union, compared with free forging, material consumption of rolled rings is reduced by 40% to 50%, and the production cost Reduced by 75%.

(6) Material diversification. With the development of aerospace technology, a large number of annular parts such as casings, sealing rings and mounting edges of aerospace engines are made of highly alloyed aluminum alloys, heat-resistant and corrosion-resistant stainless steel, alloys and high-temperature alloys. The common characteristics of these materials are Due to their high deformation resistance, poor fluidity, and narrow processing window, and because these materials are expensive and require high structural and performance requirements for custom forgings, there is an urgent need to develop precision rolling forming technology for special alloys.

Comments

Please Join Us to post.

0